SUCCESS IS A TURN-KEY RIGGER

Moving a stamping press across the shop floor? Relocating an entire plant cross country? Lee Contracting’s experienced industrial rigging services team makes sure the job is done with minimal downtime and maximum safety.

Our decades of experience, industry-leading equipment and technical know-how enable us to analyze, plan, move and reassemble your next rigging project with maximum results and cost efficiency.

As a single-source solution, we self-perform every phase of your project, giving you one point of contact for every job. Working with a single project manager saves time and enables a seamless workflow.

Discovered an issue on a project? That usually means holding up the rigger while you contact a sub to address the problem. Which stops your job until the issue is resolved. Even then, your rigger may have moved on to another job, resulting in waiting for them to find an open slot in their schedule to fit you in.

With Lee’s single-source solution, we have all the resources in-house to fix any problem quickly so you never lose your place in line.

TOTAL IN-HOUSE RIGGING RESOURCES FOR ANY PROJECT

Single-source also means we own the equipment needed to make your project a success. From 200,000 pound fork trucks to 800 ton gantry systems to our million pound Goldhofer transport module, your project will never be delayed waiting on equipment. That’s a claim most contractors can’t make.

- Equipment ownership ensures our operators personally know the machinery they’re running. We’re operating experts with daily experience in equipment procedures.

- We employ state-of-the-art computer modeling to help us efficiently plan moves in detail and identify any potential hazards.

- With in-house fabrication, we can engineer unique ways to move things, getting into places other contractors can’t and often avoiding complete disassemblies.

With decades of industrial rigging services experience, we know the ins and outs of the process. And we’ve learned a thing or two along the way. Rest assured, we’re applying every lesson we’ve learned to your project.

HAZARDOUS JOBS DONE SAFELY

Rigging jobs carry a high risk by their very nature. That’s why we include planning for safety at the start of every rigging project. Performing safely doesn’t end with the plan. We begin every workday with a site inspection and discussion of the day’s work with everyone involved. Our commitment to jobsite safety is more than just words on a page: every employee on-site has the power to stop the job if anything doesn’t seem right.

RIGGING SERVICES

- Proprietary Roof Raise Process

- Millwright Services

- Stamping Presses

- Steel Cells

- Paper Mills

- Assembly Lines

- IMM & BMM

- Weld Cells

- Power Generation Facilities

- Precision Alignment

- Precision Leveling

- Machinery Equipment

- Structural Steel

- Equipment Rebuilds

- HVAC Systems

- Robotic Cells

- Overhead Crane Installation

- Food Processing Facilities

- Pharmaceutical Facilities

- Cleanrooms

- Paint Booths

- Electric Vehicle Charging Stations

- Commercial & Municipal Utilities

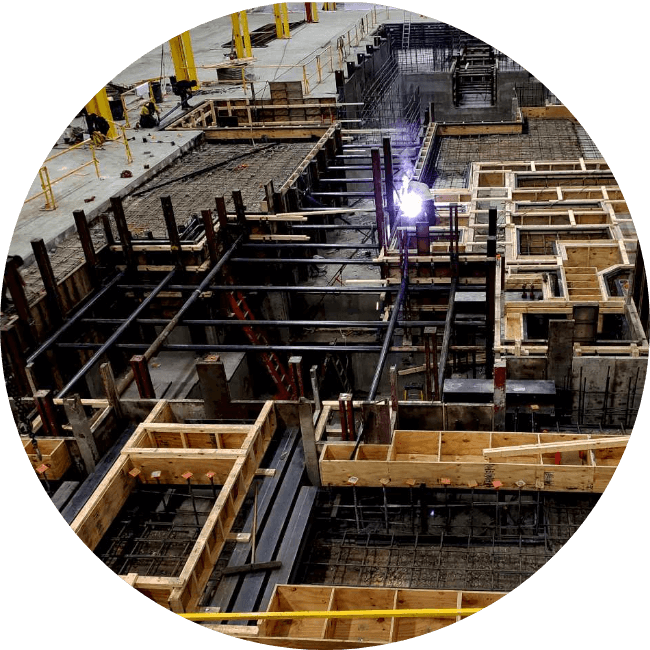

Featured Rigging Project

CRANES AND CHAINS

Lifting 600 kiln chains 800 feet through a 26 inch manway. Lee riggers get it done.