You’ve been hearing it since kindergarten: Safety first! It’s a solid rule of life, but on an industrial contracting site, safety is more than a catchy slogan. Before even setting foot on the job site, an industrial contractor must have in place a systematic set of safety protocols and standards that workers must follow at all times.

Whether it’s constructing a new facility, installing heavy machinery or performing routine maintenance tasks, a reputable industrial contracting company will prioritize safety above all else. These are some of the key areas we focus on.

Safety Training

Training workers on safety measures it not a one-and-done endeavor. Continuous training is needed to ensure safety remains top of mind and to keep staff abreast of the latest compliance regulations. The training should cover a wide range of safety-related topics, including hazard recognition, proper equipment usage and emergency procedures. When the workforce understands the importance of safety and has the knowledge and skills to identify and mitigate risks, everyone enjoys a safer work environment.

Safety Protocols and Procedures

When it comes to safety, the “just wing it” approach just won’t cut it. Strict safety protocols and procedures must be established and enforced so that everyone knows exactly what to do before, during and after a job. These should include specific guidelines for a variety of situations, such as working at heights, handling hazardous materials, operating heavy machinery and managing electrical systems. By following established safety procedures, all staff will be aligned and know what to do to keep safe.

Hierarchy of Controls

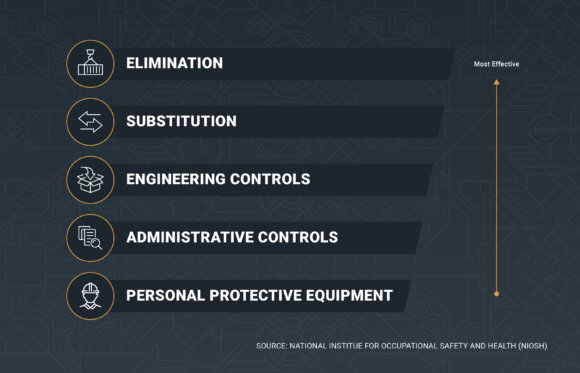

Lee Contracting strictly adheres to the “Hierarchy of Controls,” a systematic approach to minimizing workplace hazards developed by the National Institute for Occupational Safety and Health (NIOSH). This hierarchy categorizes safety measures into five levels of control, each building upon the previous one to reduce risks:

• Elimination: The essential first step is to eliminate the hazard. This may require careful assessment and planning to determine the ideal approach.

• Substitution: If elimination isn’t possible, the next best thing is substitution – replacing the hazard with a safer alternative.

• Engineering Controls: After eliminating or substituting the hazard, we modify the environment or equipment in a way that reduces the potential for accidents.

• Administrative Controls: This step involves the development of policies and procedures that staff must follow to minimize the risk of accidents.

• Personal Protective Equipment (PPE): Wearing appropriate gear such as hard hats, safety goggles, gloves and steel-toed boots are the last but important line of defense to minimize the potential for injuries.

Job Hazard Analysis and Site Inspections

Before beginning any project, industrial contractors conduct a job hazard analysis to identify potential threats. By thoroughly reviewing the job site and the job details, contractors can detect the greatest areas for risk, take measures to prevent them from happening and develop an emergency response plan. Regular site inspections and safety audits should be conducted throughout the project to ensure compliance with safety standards and pinpoint unsafe conditions.

Emergency Preparedness

Despite the most vigilant efforts to ensure safety, emergencies sometimes occur. Industrial contracting companies must have a comprehensive emergency response plan to handle accidents, injuries, fires or other unforeseen incidents. These plans outline procedures for providing first aid, evacuating the site and contacting emergency services. Having a plan in advance helps everyone stay calm and understand the precise steps to take in the event of an emergency.

Environmental Protection

Protection from environmental hazards cannot be overlooked. Safety protocols should cover measures to prevent pollution, minimize waste generation and comply with environmental regulations. This can include proper handling and disposal of hazardous materials, spill prevention protocols, and mitigation of other environmental impacts.

Building a Culture of Safety Through Collaboration

Lee Contracting prioritizes safety in every industrial contracting project. We employ a dedicated safety team that develops, enforces and maintains a world-class safety program. In addition to our safety team, we have a safety committee made up of individuals from various departments and levels within the company. By working together and getting input from various members of our community, we can maintain a safe workplace and instill a culture of safety throughout the organization. Our dedication to safety protects and builds confidence among our team, our customers and our partners.