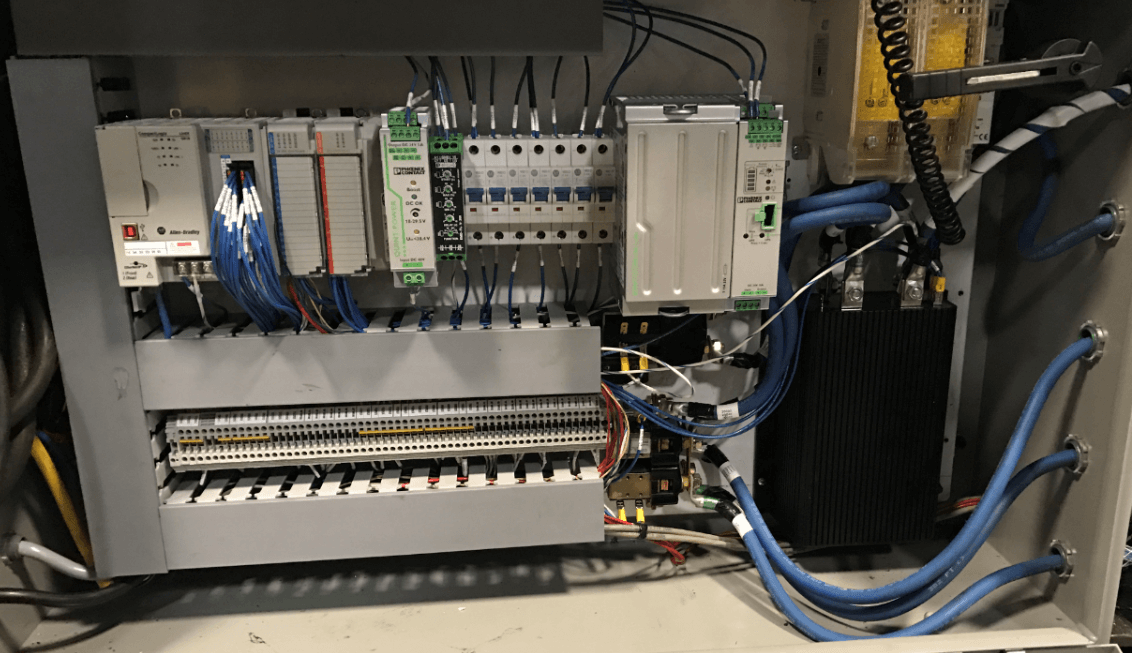

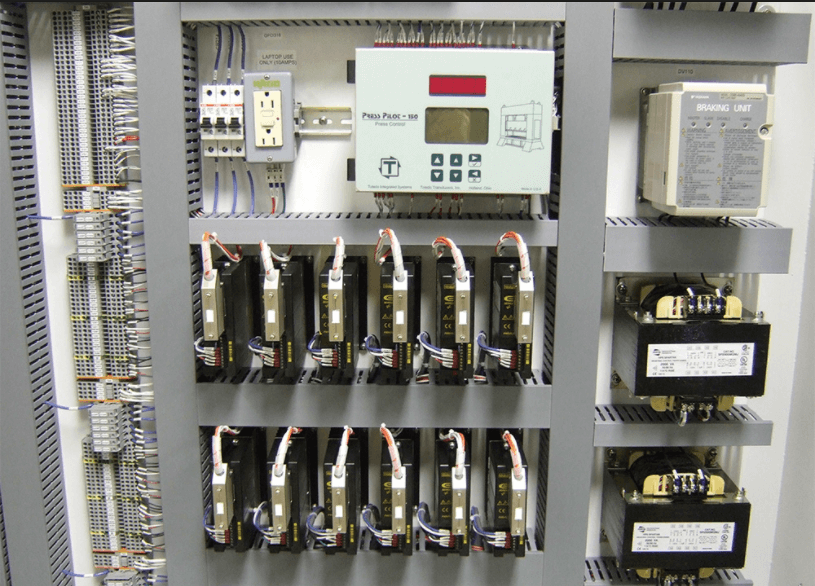

Many industries use PLCs to accurately time and program manufacturing operations. A PLC, or a programmable logic controller, is an industrial digital computer that has been adapted for use and control of manufacturing processes. It is built to withstand the harsh industrial environment of plants and factories such as intense temperatures, dampness, noise and other common disruptions.

The system is different from other controller communication systems because of its programmability and its widespread input/output array. It is easy to alter and modify a PLC’s program to fit each application’s constraint. The new PLC’s with Ethernet has greatly reduced the once time-consuming wiring process and with the low voltages used today has greatly reduced many of the electrical hazards.

A PLC comes with several distinctive functions like sequential control and ease of programming. This helps users to accurately time and program manufacturing operations. The system is based on logic controllers that are responsible for controlling and scrutinizing a large capacity of input and outputs for machine motion and operator safety.

Lee Contracting’s controls and robotics staff engineers have over 30 years of experience in the field. They have extensive knowledge of legacy systems and a comprehensive knowledge of many applications. In addition to supporting and upgrading older systems, we are fully up-to-date on the newest hardware and software platforms from all the major PLC suppliers. With our complete controls and robotics capabilities, Lee can handle the full programming of automation systems including all necessary design, development and engineering. Call today to receive a free quote, 888.833.8776.