When your manufacturing or industrial business grows, that’s generally considered a good thing. However, “growing pains” are real, and growth isn’t without its own set of challenges. One of the biggest challenges for industrial facilities is limited space for growing operations.

Expanding your facility is exciting, but it isn’t just about adding square footage – it’s about doing so efficiently, cost-effectively and with minimal disruption to production. In today’s environment, innovative tools and technologies are making facility expansion easier and more efficient, and our industrial contracting team is staying ahead of the curve.

Precision Planning in Modern Expansions

When done right, facility expansions start well before construction begins. Planning accurately ensures that every square foot of new or reconfigured space meets operational needs while minimizing waste.

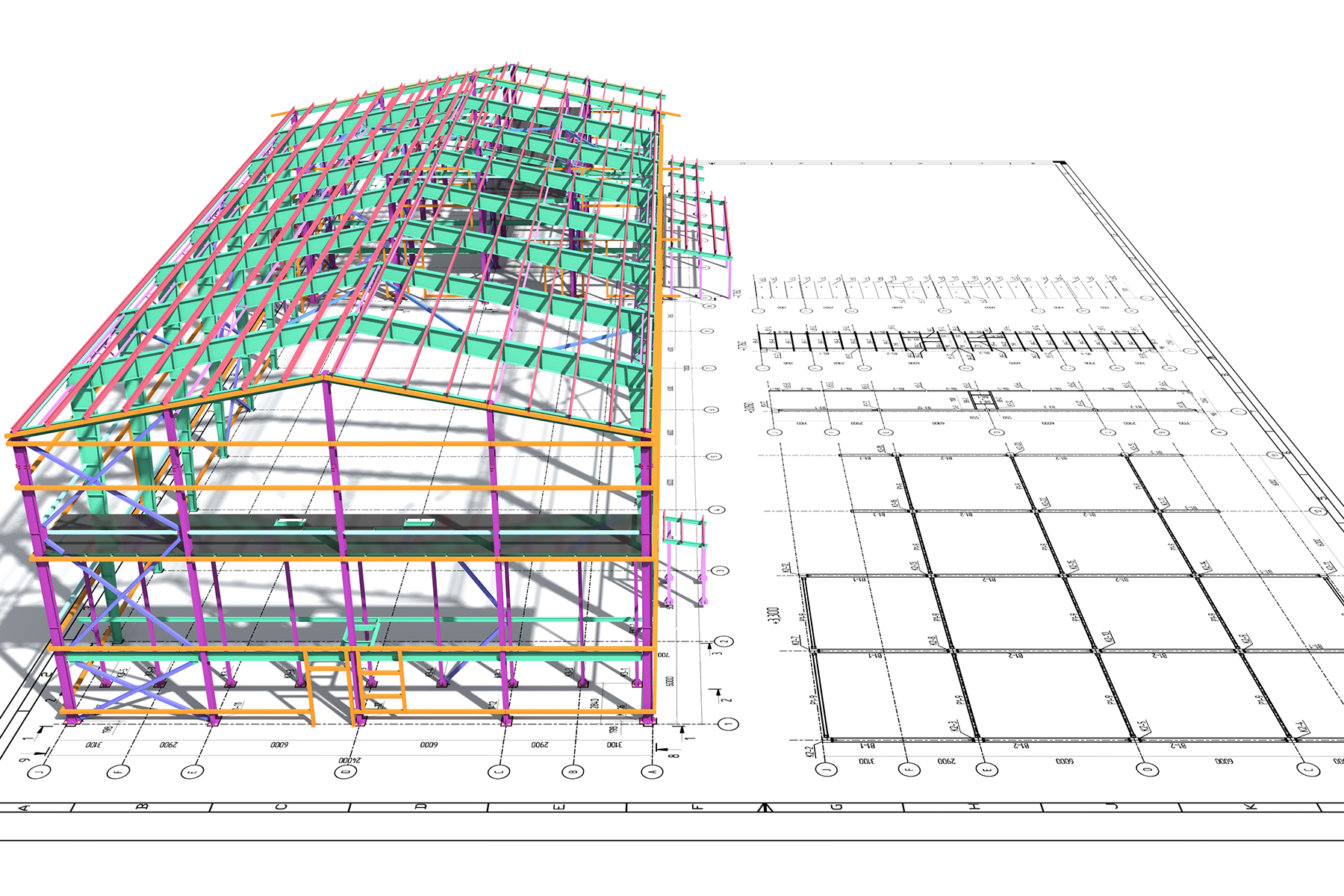

Advanced tools like Building Information Modeling (BIM) software help businesses and industrial contractors visualize, simulate and optimize their designs prior to the physical work. At Lee Industrial Contracting, we’ve embraced this technology by implementing Trimble Tekla Structures into our concrete design and engineering workflows. This powerful BIM software allows us to create highly detailed 3D models that bring clarity to every stage of an expansion project.

By identifying potential challenges early in the design phase, we can avoid costly delays and maximize the use of available space.

Taking BIM Models into the Field

The advantages of BIM software don’t stop at our planning table. One of its most significant benefits is the ability to easily share information with customers, engineers and field crews. Lee Industrial Contracting takes it further by tying the BIM data to robotic layout equipment used in the field. This ensures that designs translate perfectly into real-world execution with incredible accuracy.

For facility expansions, precision matters. Small mistakes can add up to costly delays or unusable space. By leveraging tools like BIM and robotic layout technology, we streamline construction workflows, reduce rework and maintain schedules.

Maximizing Space While Minimizing Waste

Facility expansions require balancing operational needs, speed and cost considerations. BIM tools help reduce material waste by optimizing designs and accelerate the project with ultra-precise advance planning to reduce errors on the job site.

Whether you’re expanding a production line, adding warehouse capacity or upgrading infrastructure, a streamlined approach to design and execution means faster, smarter growth.

A Forward-Thinking Approach to Facility Growth

While BIM software is slowly becoming a fixture in the foundations industry, early adopters have a clear advantage. At Lee Industrial Contracting, embracing tools like advanced BIM software isn’t just about meeting today’s needs, it’s about laying the groundwork for future growth.

Our use of BIM marks an important step toward creating even more capabilities in virtual design and construction. By integrating cutting-edge solutions into our already proven process, we’re continuing to set new standards for precision and efficiency, helping businesses achieve their expansion goals with minimal disruption to operations.

Ready to Expand? Partner with a Team That Innovates

At Lee Industrial Contracting, we believe that innovation drives efficiency. By integrating advanced tools like BIM software and robotic layout technology into our process, we’re redefining what’s possible for facility expansions.

If you’re planning to grow your operations, don’t rely on outdated methods. Partner with an experienced industrial contractor that leverages innovative technology to deliver precision, efficiency and value.

Let’s build the space you need. Contact us today to learn more about how Lee Industrial Contracting can help you grow – without the pains.